Discharge Pressure: 8-16bar

Motor Power:7.5~250kW

FAD Flow: 0.45~48.25m³/min

Energy saving, VSD drive with IE5 PM motor, low oil consumption

Discharge Pressure: 20-40bar

Motor Power:18-250kw

FAD Flow: 1.73-23.8m3/min

Screw type, Stable and reliable, low maintenance cost, Low noise and vibration

Piston air compressors use the piston to reciprocate in the cylinder to compress the air. They have high noise and vibration and many wearing parts. After the piston rings are worn, the air volume will decrease causing the decreased efficiency.

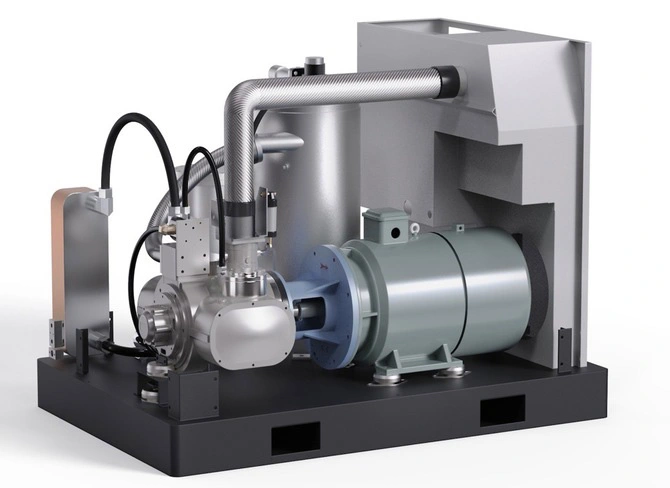

The oil-injection screw compressor, an oil-lubricated air compressor, mainly consists of a screw and star wheels to form a compression chamber. The industrial air compression process is completed through the rotation of the screw which has higher requirements for processing accuracy because higher accuracy means higher volumetric efficiency. The noise and vibration are small, the unit has no wearing parts so the maintenance cost is low.

The main components of an oil-injected air compressor are the air end, motor, oil and gas separation tank, and cooler. Since the oil requires a higher temperature to ensure its good lubricity, the oil-lubricated air compressor is generally air-cooled. The filter element filters the air and is then sucked into the air end for compression.

An industrial oil-lubricated compressor injects lubricating oil into the air end for lubrication and sealing. The compressed oil and gas mixture is separated by the separation core in the oil and gas separation barrel to get compressed air with an oil content of less than 2 ppm. After being cooled by the air-cooled cooler, the high-temperature oil returns to the compression air end and circulates continuously.

Compressors typically require a medium for lubrication to ensure long-lasting performance and stability. In an oil-injected compressor, the compressor's air end is lubricated with oil. The oil-gas mixture produced during compression is separated using a separator, resulting in the final compressed air. This oil-injected air compressor technology is well-established and widely used across various industries, making oil-injected compressors common in the market.

On the other hand, oil-free compressors provide pure, contaminant-free compressed air. For example, compressed air used in dental applications must be oil-free. This type of CMN compressor uses water as a lubricant instead of oil. Water serves as a sealant, lubricant, and cleaning agent, allowing the oil injected screw compressor to operate without any lubricating oil, thus delivering truly oil-free compressed air.