Pure water instead of lubricating oil is used in the air end for lubrication. The air end and all parts in contact with water are made of 304 food-grade stainless steel. Compressed air passes the TUV oil-free test and also meets the requirements of the FDA and GMP. With no oil in the whole water-injected screw compressor, maintenance is simple and only requires the replacement of the air and water filter. Water-injected screw compressor adopts a direct coupling method between the air end and the motor, resulting in high transmission efficiency. The water-injected compressor unit operates at an exceptionally low temperature, typically around 45 degrees Celsius, ensuring efficient cooling and energy use.

The single screw air end is composed of a main screw and two symmetrically arranged flat star wheels to form a meshing pair, installed inside the stainless steel shell. The screw's groove, the inner wall of the air end shell, and the tooth surface of the star wheel constitute the compression chamber. The motor directly drives the rotation of the screw shaft, which drives the rotation of the star wheel. The gas enters the screw groove through the suction port, undergoes compression, and is then expelled through the exhaust port on the air-end shell. There are spray holes on the air end shell for the injection of lubricating oil or water into the compression chamber, serving as sealing, cooling, and lubricating functions.

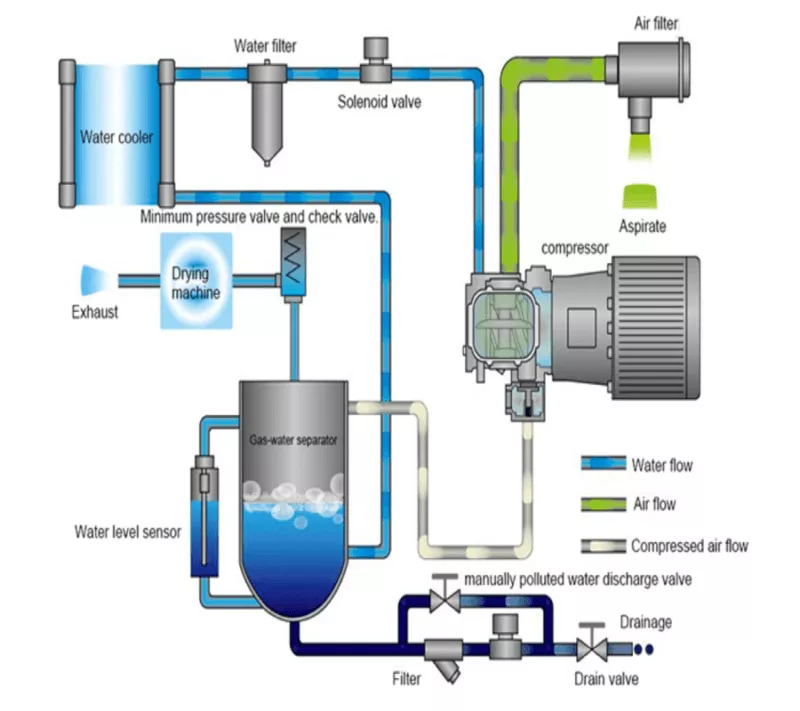

Air is sucked into the air end through the air filter, getting compressed in the air end. During compression, water is injected into the air end to cool and lubricate. The water gas mixture then is separated in a gas water separator and compressed air is discharged from the minimum pressure valve on the top of the gas water separator to the user. Water remains at the bottom of the gas water separator, being cooled by the water cooler or air cooler, and goes to the air end for compression again.

No oil air compressor finds extensive applications across various industries. In the pharmaceutical and food industries, compressed air is utilized to stir and convey raw pharmaceuticals or food ingredients. Compressed air is in direct contact with drugs or food, so the quality(oil content, bacterial content, dust content) of water-injected compressors is highly demanded, requiring compliance with GMP or FDA regulations. CMN has a perfect food-safe air compressor with no oil pollution, contributing to the effective production of compressed air qualified in the food and medical industry. In the electronic or semiconductor industry, no oil compressor can be used to clean circuit boards or convey electronic components. Also, oil free air compressors in China can provide a pure air source for various precision instruments.

The whole water-injected compressor is free of any lubricating oil, ensuring an oil-free compressed air supply.

The operating temperature of the water-lubricated compressor is low, typically below 45 degrees Celsius.

Low maintenance costs, requiring only the replacement of air and water filters.

Isothermal compression, high efficiency with direct coupling of the air end and motor.

The air end rotates at a speed of only 3000 revolutions per minute, resulting in low noise and vibration.

Lifetime Oil free Guaranteed

Stability---Stably compress your air for at least 10 years

Easy maintenance---No wearing parts design

If you need oil-free air compressor solutions, feel free to send us an inquiry!