The raw materials of plastic bottles must meet relevant national standards, especially medicinal bottles must meet medical and health requirements. There are four common raw materials for plastic bottles, polypropylene (PP), polyester (PET), polystyrene (PS), polyethylene (PE), etc. With PET compressed air, the materials are made into different forms of bottle containers.

1. Polypropylene (PP)

It has low density, and its strength, hardness, and heat resistance are better than those of high-density polyethylene. However, it becomes brittle at low temperatures, is not wear-resistant, and is prone to aging. However, corresponding additives can be added for modification, and the performance level of HDPE can be achieved after modification.

2. Polyester (PET)

PET has many advantages as a packaging container for pharmaceuticals such as eye drop bottles. PET bottles are light and strong, with significantly higher strength and elasticity than plastic bottles made of other plastic materials. Among commonly used plastics, they have better performance in blocking water vapor and oxygen. PET bottles have good chemical resistance and can be used for packaging all items except strong alkalis and some organic solvents. PET bottle compressors are suitable for making thin-walled, lightweight, and high-strength pharmaceutical packaging bottles. Therefore, PET bottles have gradually replaced traditional glass bottles.

3. Polystyrene (PS)

Colorless and transparent, its light transmittance is second only to organic glass, and it has good colorability, water resistance, and chemical stability. However, PS raw materials are brittle, have average strength, are prone to stress brittle cracking, and are not resistant to organic solvents such as benzene and gasoline, so they are rarely used in the field of pharmaceutical packaging. However, after modification, the impact resistance of the material can be greatly improved.

4. Polyethylene (PE)

It is corrosion-resistant and can be chlorinated. Polyethylene is divided into high density (HDPE), low density (LDPE), and linear low density (LLDPE). HDPE has a high melting point, hardness and strength, low water absorption, good processability, and radiation resistance, and is often used to produce plastic bottles for tablets. LDPE has good softness, elongation, and impact strength and can be used in plastic bottles for eye drops. LLDPE has high impact strength, fatigue resistance, and wear resistance, and is rarely used in pharmaceutical packaging such as eye drop bottles.

PET is the most widely used beverage packaging material today. PET bottles originated in the early 1980s. Due to their lightweight, easy forming, low price, and easy mass production, this compressor for pet blowing machines has developed rapidly and with unstoppable momentum since its inception. In just about 20 years, bottle blowing air compressors have developed into the most important form of beverage packaging in the world. PET is not only widely used in the packaging of medicines, carbonated drinks, bottled water, condiments, cosmetics, liquor, dried fruit candies, edible oils, pesticides, and detergents, but also specially treated special filling bottles can also be used for juice and tea beverage packaging.

There are usually three ways:

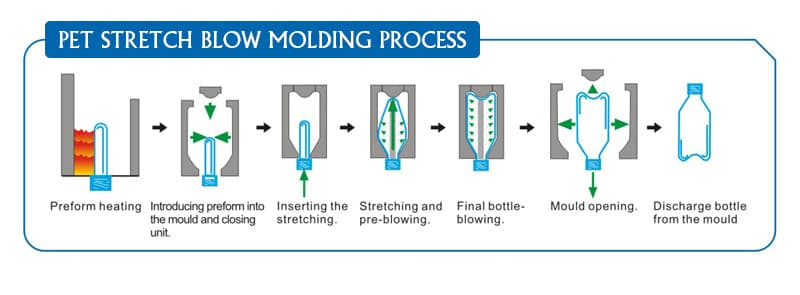

In blow molding, the tubular plastic parison obtained by extruding the raw material is placed in a split mold while it is hot. Immediately after the mold is closed, pet compressed air is inserted into the parison to inflate the plastic parison and stick to the inner wall of the mold. After cooling, the pet bottle compressor mold is opened to obtain various hollow products. CMN pet bottle air compressor is primarily used to manufacture beverage bottles, jars, cosmetic containers, medicine bottles, and more.

Injection molding uses pressure to inject molten plastic into plastic product molds, and then cools and molds it to obtain various plastic parts. There are specialized machines and molds for injection molding, with large outputs and low prices. Injection molding has the widest range of products. As long as there is a mold, products can be made, and it is very convenient.

In blister molding, a flat hard plastic sheet is heated and softened, then vacuum adsorbed to the mold surface, and then cooled and formed. It saves raw and auxiliary materials, is light in weight, and is easy to transport. The products are generally relatively shallow, such as basins, flat plates, and other products with large and relatively shallow diameters.

For the application of blowing molding, usually, a pressure of 20~40 bar compressed air is applied. For the application of injection molding, a pressure of 6~10 bar compressed air is applied. If the plastic container is used for food, beverage, pharmaceutical, or cosmetic products, oil free compressed air is required.

Model selection is important as it can reduce energy consumption and prolong the machine's life. The capacity of the compressor for pet blowing machine, whether used or not, air-cooled or water-cooled shall be taken into serious consideration before purchasing.

Stability

For the air compressor for the PET blowing machine, we put stability in the first place, as we understand that the loss caused by the breakdown of the PET bottle air compressor that affects the production is huge.

Oil-free

Oil pollution from PET bottles is fatal to some companies as it influences the corporate reputation, CMN oil-free PET bottle blowing air compressor adopts a real oil-free design(the whole machine does not contain lubricating oil).

Low operating cost

CMN plastic bottle compressor machine uses screw-type compression with no wearing parts design. Maintenance is easy with the lowest cost. Vibration and noise are also much reduced compared to reciprocating air compressors.

If you need a compressed air solution for your PET bottle-blowing application, feel free to reach out to our professional team.