Due to the contact between the mechanical components during rotation, lubrication with a certain medium is required.

For an oil-injected air compressor, the air end is lubricated with lubricating oil. Air and oil are mixed and compressed in the air end, resulting in compressed air with oil.

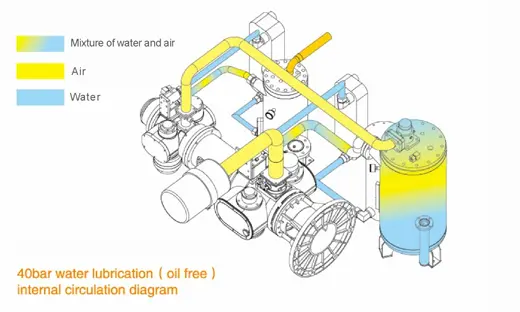

The oil-free air compressor is lubricated with water instead of oil. Water is injected into the air end and compressed with air, serving the functions of lubrication, sealing, and cooling. The industrial mixture is separated through a water gas separation tank, supplying pure oil-free compressed air.

Maintaining the oil-free screw air compressor is simple and convenient. Regular maintenance for oil free compressor mainly involves replacing the air filter and water filter cartridge, a task that can be done by the user in about 10 minutes. For the screw air end, maintenance is required after 10,000 hours (approximately 2 years) of total operation, and this process typically requires assistance from the manufacturer’s engineers. CMN, a trusted oil-free compressor manufacturer, ensures optimal service with the support of industry experts.

What sets CMN oil-free screw compressors apart from oil-lubricated models is their use of water lubrication technology. This means no lubricating oil is needed, eliminating the need for oil-related maintenance.

In the market, there are two main types of oil-free screw compressors: non-lubricated compressors and water-lubricated compressors. Non-lubricated compressors run at higher speeds and require oil for gearbox lubrication, which means regular oil changes are necessary. On the other hand, water-lubricated compressors from CMN do not require oil changes, making them much easier to maintain and more convenient for the user, it also ensures to supply of 100% oil-free air.

Oil-free air compressors are particularly suitable for industries such as pharmaceuticals, food processing, electronics, and textiles. In these sectors, compressed air comes into direct contact with food, medicine, or other sensitive products, so clean, contaminant-free air is crucial. Oil-free compressors help prevent contamination and protect the integrity of products, which is essential for maintaining a company's reputation. CMN, a reputable China oil-free air compressor manufacturer and supplier, provides you with superior oil-free compressors designed for your needs.

In addition to industry regulations requiring oil-free compressors for certain applications, CMN also offer cost benefits in terms of maintenance. Compared to oil-lubricated compressors, oil-free air compressors generally have lower maintenance and operational costs, making them an economical choice in the long run.

The typical lifespan of a non-lubricated screw air compressor on the market ranges from five to ten years. After about three years of operation, the oil free air compressor's air end often requires major repairs to prevent significant air volume reduction, which can result in high maintenance costs.

CMN oil-free screw air compressors, manufactured by one of the leading China oil-free compressor suppliers with over 20 years of experience, are designed for long-term reliability. With numerous customer cases where the compressors have been in use for more than ten years, CMN industrial electric air compressors are known for our low maintenance costs and durability. These non-lubricated air compressors are designed with a lifespan of over 20 years, and in practice, they typically last for more than 15 years.

CMN, as an oil-free compressor supplier, products include screw-type compressors and scroll-type compressors.

In an industrial screw air compressor, the air end consists of a main screw and two-star wheels. Air filtered through an air filter is sucked into the air end, and the motor drives the air end to rotate. During the rotation, the volume of the compression chamber formed by the screw and star wheels continuously decreases, compressing the air to the high-pressure end. The compressed air then enters the water gas separation tank for centrifugal separation, compressed air is discharged through the minimum pressure valve.

The scroll air end is composed of a stationary disk and a moving disk, forming a compression chamber.